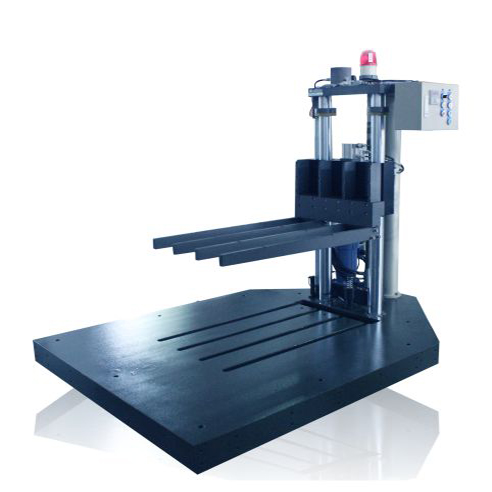

Heavy-load pallet drop tester KD-500, KD-500

KD-500

Heavy-load pallet drop tester KD-500

To evaluate impact effects of shock, drop and tumble encountered in repair and handling process, so do the safety strength assessment.

The general drop test is against bottom, angle, edge and tumble. According to related specifications you can lift one side of the product by angle to make it drop freely.

All new developing products must undergo several strict testing processes while in designing, manufacturing and packing/ shipping even. Our drop tester will provide data digitizing and analyzing of your drop and striking while the products in transportation. The testing data will help you improve the packing and buffer materials.

All new developing products must undergo several strict testing processes while in designing, manufacturing and packing/ shipping even. Our drop tester will provide data digitizing and analyzing of your drop and striking while the products in transportation. The testing data will help you improve the packing and buffer materials.

This tester follows CNS 2999 (packing and transporting vessel drop test method) to make design; having varied types of packing and transporting vessels be drop-tested precisely against angle, edge and plain surface.

Tester is off precisely and would never hit the specimen; the hiting plane won’t incline.

Packaged drop test is applied to test the anti-vibration & covering capability of packaging material and the sufficiency of product’s impact-resisting capability regarding packaged products. And use the test result to determine how to improve the packaging design. Free drop test is used to assess the characteristics of product’s free fall from improper actions; and evaluate the required strength and toughness of product under safety conditions.

Repeated free fall test is to simulate object’s condition after normal fall to hard surface.

KD-500

0~1300