Product

Home > Product > Vibration Tester

- Coil structure earns Taiwan & USA patents.

- Slip table is driven by linear low-noise hydraulic pump.

- Side & bottom plates are made of cast steel; own the feature of high stiffness and low resonance.

- Machine body is under air-bellow & hydraulic damper protection; no anchor required.

- Machine body is stable and won’t influence floor structure or interfered by external vibration source.。

- 2 ~ 5,000 kgF (10,000kgF~Max)

- DC~2,000 Hz option(20,000Hz~Max)

| KD-9363 | 推理值 Force(kgF) |

频率范围 Usable Freq Range(Hz) |

动圈重量 Mass of Armature(kg) |

动圈直径 Armature Diameter(mm) |

加速度 Sine Peak Acc(g) |

位移 Max Disp(mm) |

载重 Load Support Capacity(kg) |

冷却方式 Cooling Method |

|---|---|---|---|---|---|---|---|---|

LT-2 |

2 |

1~20,000 |

0.08 |

30 |

25 |

5 |

0.5 |

气冷 Gas Cooling |

LT-5 |

5 |

1-10,000 |

0.20 |

70 |

25 |

10 |

1 |

气冷 Gas Cooling |

LT-10 |

10 |

1~10,000 |

0.50 |

70 |

20 |

15 |

2 |

风冷 Air Cooling |

LT-30 |

30 |

1~4,000 |

1.50 |

70 |

20 |

20 |

5 |

风冷 Air Cooling |

EM-100 |

100 |

1~4,500 |

4 |

90 |

25 |

25 |

70 |

风冷 Air Cooling |

EM-200 |

200 |

1~4,000 |

4 |

140 |

50 |

25 |

70 |

风冷 Air Cooling |

EM-400 |

400 |

1~4,000 |

9 |

150 |

44 |

40 |

140 |

风冷 Air Cooling |

EM-600 |

600 |

1~4,000 |

12 |

200 |

50 |

51 |

300 |

风冷 Air Cooling |

EM-1000 |

1,000 |

1~4,000 |

15 |

200 |

67 |

51 |

300 |

风冷 Air Cooling |

EM-1000-L |

1,000 |

1~4,000 |

18 |

260 |

56 |

76 |

300 |

风冷 Air Cooling |

EM-1500 |

1,500 |

1~4,000 |

20 |

200 |

75 |

51 |

300 |

风冷 Air Cooling |

EM-1500-L |

1,500 |

1~4,000 |

25 |

260 |

60 |

76 |

300 |

风冷 Air Cooling |

EM-2000 |

2,000 |

1~4,000 |

35 |

330 |

57 |

51 |

300 |

风冷 Air Cooling |

EM-2000-L |

2,000 |

1~4,000 |

40 |

330 |

50 |

76 |

300 |

风冷 Air Cooling |

EM-3000 |

3,000 |

1~3,000 |

40 |

450 |

75 |

51 |

500 |

风冷 Air Cooling |

EM-3000-L |

3,000 |

1~3,000 |

45 |

450 |

67 |

76 |

500 |

风冷 Air Cooling |

EM-4000 |

4,000 |

1~3,000 |

60 |

450 |

67 |

51 |

800 |

雾化水气 Atomization Cooling |

EM-4000-L |

4,000 |

1~3,000 |

65 |

450 |

62 |

76 |

800 |

雾化水气 Atomization Cooling |

EM-5000 |

5,000 |

1~3,000 |

65 |

450 |

77 |

80 |

800 |

雾化水气 Atomization Cooling |

EM-6000 |

6,000 |

1~3,000 |

80 |

450 |

75 |

80 |

1,000 |

雾化水气 Atomization Cooling |

EM-7000 |

7,000 |

1~2,500 |

90 |

445/550/650 |

78 |

80 |

1,000 |

水冷 Water Cooling |

EM-8000 |

8,000 |

1~2,500 |

100 |

445/550/650 |

80 |

80 |

1,000 |

水冷 Water Cooling |

EM-10000 |

10,000 |

1~2,500 |

120 |

445/550/650 |

80 |

80 |

1,000 |

水冷 Water Cooling |

EM-12000 |

12,000 |

1~2,500 |

140 |

445/550/650 |

80 |

80 |

1,000 |

水冷 Water Cooling |

|

|

| Obtained the award of excellent product design in 2001. | ROC Patent New-type 091293 |

![]() Electromagnetic Shaker

Electromagnetic Shaker

Coil structure earns Taiwan & USA patents.

Coil structure earns Taiwan & USA patents.

Vibrator body is by air-bellow damping design; body’s natural frequency won’t influence floor structure or interfered by external vibration source.

Vibrator body is by air-bellow damping design; body’s natural frequency won’t influence floor structure or interfered by external vibration source. Vibrator is by dual magnetic circuit’s design; the high magnetic alloy and H/APTZ-level coil can generate the best magnetic effort. The body & coil cooling system follows cooling airflow design that can ensure system’s stability.

Vibrator is by dual magnetic circuit’s design; the high magnetic alloy and H/APTZ-level coil can generate the best magnetic effort. The body & coil cooling system follows cooling airflow design that can ensure system’s stability. The overall system is made by gravity casting; beautiful shape and strong; the bottom & side plates are made of spherical graphite cast steel, firm and with a low resonance frequency.

The overall system is made by gravity casting; beautiful shape and strong; the bottom & side plates are made of spherical graphite cast steel, firm and with a low resonance frequency. Low-noise direct-connecting pump

Low-noise direct-connecting pump

Hydraulic pressure regulator and gauge indicator

Hydraulic pressure regulator and gauge indicator Pressure-error indication and alarm

Pressure-error indication and alarm  Air-bellow dampers x 6

Air-bellow dampers x 6 System is designed at 3~5 Hz low resonance frequency; not influence floor structure.

System is designed at 3~5 Hz low resonance frequency; not influence floor structure. Class A Granite platform / linear hydraulic pump

Class A Granite platform / linear hydraulic pump Slip table is made of Mg/Al alloy and military-standard super-hard anodizing; the surface hardness exceeds HR C60 & HV400.

Slip table is made of Mg/Al alloy and military-standard super-hard anodizing; the surface hardness exceeds HR C60 & HV400. Precise linear ball guider; no lateral vibration.

Precise linear ball guider; no lateral vibration. Mg/al die cast alloy

Mg/al die cast alloy

Table is made of aluminum alloy and military-standard super-hard anodizing

Table is made of aluminum alloy and military-standard super-hard anodizing Free from bolting; save time; worm-linked gear mechanism; labor-saving

Free from bolting; save time; worm-linked gear mechanism; labor-saving

Automatic positioning bolt; wheel braking device, no sliding danger.

Automatic positioning bolt; wheel braking device, no sliding danger. Over displacement; over current; coil temperature error indication; power amplifier

Over displacement; over current; coil temperature error indication; power amplifier

Temperature error and exhaust fan error indications, amplifier N.TR/P.TR error indication and emergency stop indication; 10 error-digits indicator.

Temperature error and exhaust fan error indications, amplifier N.TR/P.TR error indication and emergency stop indication; 10 error-digits indicator. Power efficiency: 96% (save several hundred thousand NTD per year and reduce massive hot air exhausted; save air conditioning power expense and improve working environment.)

Power efficiency: 96% (save several hundred thousand NTD per year and reduce massive hot air exhausted; save air conditioning power expense and improve working environment.) Accuracy is set at 0.1%

Accuracy is set at 0.1%  Can set over current, over voltage and noise detection/protection as well as many output limits.

Can set over current, over voltage and noise detection/protection as well as many output limits.

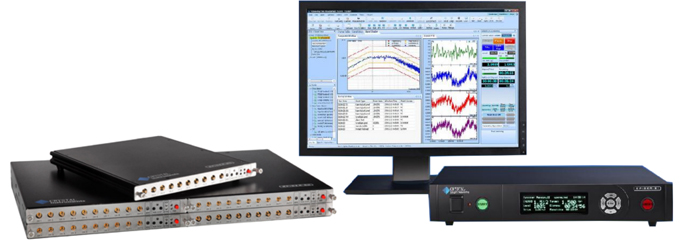

The LASER USB vibrator control system leads the vibration test into a USB 2.0 era. In the vibration controller field it first applies the new generation’s transmission interface. The control software has accepted the opinions from many R&D and production engineers, which makes the LASER USB vibrator control system more close to the four demands that operator concerns most: Convenience, high-performance, flexibility and security.

Can extend to 16 input channels at most.

Can extend to 16 input channels at most.  USB 2.0 transmission interface

USB 2.0 transmission interface  Windows 2000/XP

Windows 2000/XP  Vibration control functions--sinusoidal sweep, random wave vibration, classical shock wave and other hybrid and more complex control functions.

Vibration control functions--sinusoidal sweep, random wave vibration, classical shock wave and other hybrid and more complex control functions. 24-bit resolution

ICP

ICP